Our MISSION: Meet or Exceed Customer Expectations for Quality & Delivery

Top Management is committed to providing quality products and services to its customer and to continually work to enhance customer satisfaction.

Our Quality Management System is company-wide and includes and covers all functions of the organization. This system is based on process development and control. All procedures and functions are identified and assigned to appropriate operational managers for implementation and execution. Execution of these processes in day-to-day operations and activities is mandatory and followed diligently by our highly trained and skilled employees.

Our Quality Policy is understood, implemented and maintained at all organization levels, as well as reviewed periodically for its continuing suitability and effectiveness.

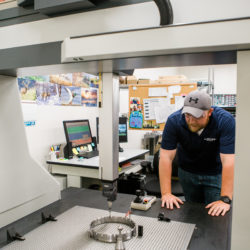

CM Manufacturing INSPECTION CAPABILITIES

VICI Vertical Vision Measuring

System MTL 500 Ergon

Measuring Range 2.36″x19.685″

Repeatability .000015-.0001

Starett HB400 Optical Comparator

X Axis 0-12” , Y Axis 0-6” , ± 10mm

Brown & Sharp G2000 Coordinate

Measuring Machine

Measuring Range 18” X 20” X 16”

Capacity 22” X 29.5” X 19”

Resolution 0.0000025

Sheffield Endeavor 2 Automated

Coordinate Measuring Machine

Measuring Range 36” X 36” X 26”

Repeatability .0001

Trimos V Plus Height Gauge

Measuring Range 0-24”

Repeatability .0001

Trimos V600+ Plus Height Gauge

Measuring Range 0-24″

Repeatability .0001

Trimos V3 & V5

Measuring Range 0-16”

Repeatability .0001

Thread Gages

Ranging from .086”-8.000”

Holematic Digital Bore Gauge

Measuring Range 0.250”-6.000”

Repeatability .0001

Micrometer

Measuring Range 0.0″-13″

Repeatability .0001

Blade Micrometer

Measuring Range 0.0″-4″

Repeatability .0001

Pitch Micrometer

Measuring Range 0.0″-6″

Repeatability .0001

Take A Tour Through our Quality Dept!

Take A Tour Through our Quality Dept!